Dosing Systems

Multi-washing dispenser TS1

Multi-washing dispenser TS1 is a centralized dosing system for chemical products, compact and scalable for both pumps and washing machines.

Dosing is carried out by means of an electric diaphragm metering pump and a suction manifold.

The pump is cleaned with water after each dosage, which extends its useful life by being always clean, prevents the products from mixing with each other, as well as undesirable chemical reactions.

This dispenser is practically maintenance free!

Recommended for OPL, washer extractors from 8 to 32kg.

Pumps: They guarantee a high degree of dosing accuracy and a long-life cycle with practically no need for maintenance. High level of security for the user and the process.

Constant and reliable dosage over time. Its membrane made of Teflon© is compatible with all chemical products used in laundries. Unlike peristaltic pumps there is no need for annoying and unproductive tube replacement.

Features: Autonomous management program (we can fully configure the equipment without the need for a PC). Process PLC, 5” color touch screen, Wi-Fi, network connection, USB port and optionally remote connection.

Register the data of the washing process generating complete reports. Detection and registration of minimum level of products, water and air.

Multi-machine equipment TS2

Multi-washing dispenser TS2 is a centralized dosing system for chemical products, compact and scalable for pumps, products and washing machines.

Dosing is carried out by means of an electric diaphragm-metering pump and a suction manifold. The pump is cleaned with water after each dosage, which extends its useful life by being always clean, prevents the products from mixing with each other, as well as undesirable chemical reactions.

This dispenser is practically maintenance free!

Wash-extractors from 22 to 300kg.

Pumps: They guarantee a high degree of dosing accuracy and a long-life cycle with practically no need for maintenance. High level of security for the user and the process. Constant and reliable dosage over time.

Its membrane made of Teflon© is compatible with all chemical products used in laundries. Unlike peristaltic pumps there is no need for annoying and unproductive tube replacement.

Features: Autonomous management program (we can fully configure the equipment without the need for a PC). Process PLC, 7” color touch screen, Wi-Fi, network connection, USB port and optionally remote connection. Register the data of the washing process generating complete reports.

It allows to integrate the dispenser in the intranet of the client. Detection and registration of minimum level of products, water and air.

CBW Tunnel Laundry Dispenser – TS Tunnel

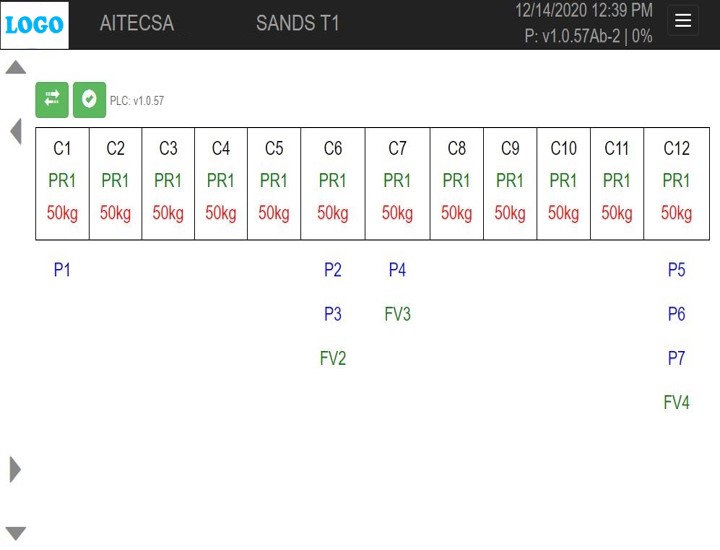

TS Tunnel: Simultaneously doses chemical products to CBW using a maximum of 16 metering pumps per tunnel, this reducing dosing time to the minimum possible. Tunnels with up to 20 compartments each displaying them on the screen.

Programs or formula are counted when exiting the last chamber. It allows automating tunnels with old controllers and only 2 valid signals. It also has flush water or air.

Pumps: They guarantee a high degree of dosing accuracy and a long-life cycle with practically no need for maintenance. High level of security for the user and the process. Constant and reliable dosage over time.

Its membrane made of Teflon © is compatible with all chemical products used in laundries.

Possibility of connecting all types of metering pumps, distribution manifolds, digital flow meters.

Features: Autonomous management program (we can fully configure the equipment without the need for a PC). Process PLC, 7” color touch screen, Wi-Fi, network connection, USB port and optionally remote connection. Optionally, flow meters can be installed.

It allows to integrate the dispenser in the intranet of the client.

Dual mode: You can select operation in relay mode or automatic mode managed by the dosing equipment.

Signals: Time combination, binary code, relay mode. 1 transfer signal. 1 Stop / Run signal. We will have up to 99 programs or formula.