Fluid Handling

Automatic Transfer of Chemical Products

This system can transfer chemical products, managing both the replenishment of product from the destination tank and its anti-overflow system.

Level detection is carried out by means of a float appropriate to the chemical nature of the product to be transferred and the operating voltage is 24VDC.

The electronic system can be calibrated for any size of tanks, and these can be of different capacities and shapes.

In normal operation, the equipment indicates on the screen the product number, numbered in groups from 1 to 7, that it is transferring.

The equipment detects if the containers or nurse tanks are empty, if the pumps do not work, or if for any reason the product is not transferred, without the need for probes or sensors in them.

In the previous case, the equipment will give us an acoustic-luminous alarm and it will indicate on the screen the number of the deposit that has caused the problem.

The anti-overflow buoy system is totally independent from the electronic controller and remains active even in the event of its total failure,

guaranteeing the blocking of the system in case of failure by activating the relevant alarm.

Hand Pumps

The range of hand pumps makes dispensing any product effortless and frustration free.

It is the most economical and reliable manual liquid transfer system for drums, barrels, IBCs and tanks. Made of FDA approved polypropylene (PP) and LDPE.

They can be used safely whether pumping corrosive acids or bases or the most innocuous of food liquids.

Exceptional performance in every pumping, making your job safer and easier, even for high viscosity liquids 8800cps.

As the world's only fully repairable hand pump, its reliability and performance are assured throughout its lifetime. Made in USA / NZ

For 25 to 200 litre drums and IBC containers

CHEMICAL COMPATIBILITY:

Excellent chemical compatibility and food safety.

Manufactured from superior quality FDA approved polypropylene and LDPE, the drum pumps are highly resistant to chemicals, including mild solvents.

Resistant to acid, caustic agents and chlorine-based chemicals.

Pumps soaps, cleaning chemicals, disinfectants, udder ointment, liquid fertilizer, antifreeze, AdBlue (DEF), battery acid, and moisturizers.

Pumps dairy hygiene products, udder ointment, liquid fertilizers, herbicides.

Pumps liquid foods, including water, milk, olive oil, acetic acid, sauces, food coloring, honey and molasses.

Approved by the Japanese Food Hygiene Agency.

Manufactured under conditions that guarantee that your liquids will not be contaminated during pumping.

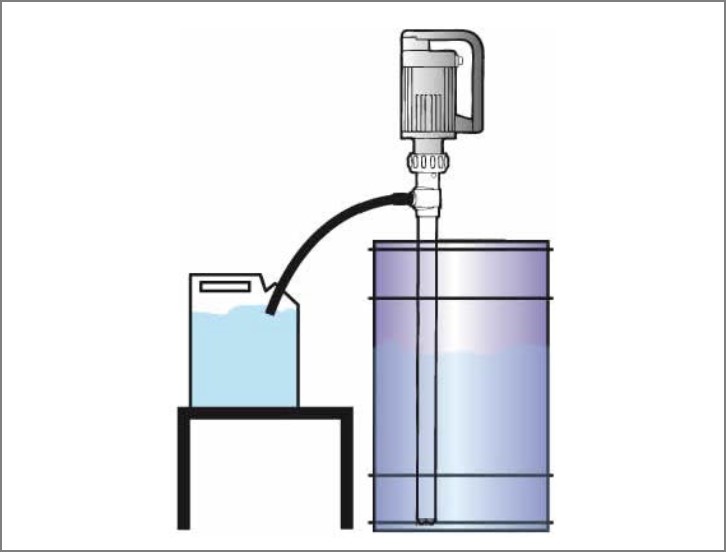

Electrical Drum Pump

Ideal for IBC containers or tanks,they are especially suitable for pumping fluids. Suitable for corrosive fluids.

Pump Construction Materials:

TR-PP: Pump made with PP [MaxTemp: 60ºC]

TR-PVDF: Pump made with PVDF [MaxTemp: 95ºC]

TR-INOX: Pump made with Stainless Steel AISI316 [MaxTemp: 95ºC]

TRX: Pump made with Stainless Steel AISI316 PTB 03 Atex 400X II1/2 GB IIB T4 [MaxTemp: 95ºC]

Engines:

800W Engine. 230V Single-phase for viscosity up to 900cps

800W Engine. 230V Single-phase, AtexII 2G Eex IIA T6

0,33CV Pneumatic Engine

Storage chemicals products

Project dyes textile industry. Storage of 22 chemicals products in Polyethylene tanks, supported on steel structure. Design and installation of pneumatic groups for transferring them into bombs. Installation of pipes and tanks levels.